Expanding access to digital fabrication, so anyone can make anything.

01765 694 007

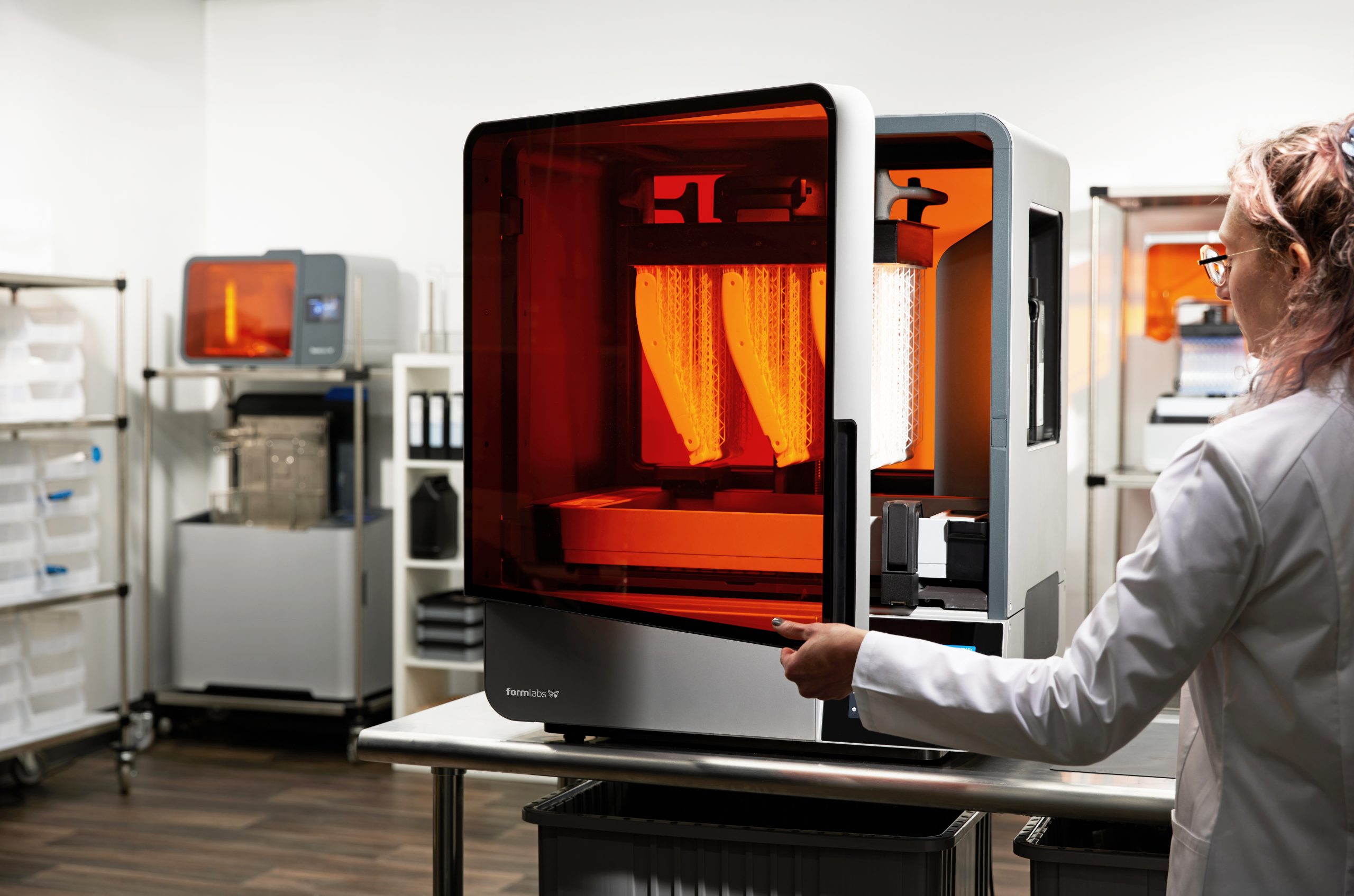

Additive-X has been a proud partner of Formlabs since the early days of the Form 1. Their cutting-edge SLA technology, called Low Force Stereolithography (LFS), along with the innovative benchtop Selective Laser Sintering (SLS) Fuse Series, continues to push the boundaries of affordable 3D printing. We offer the complete range of Formlabs printers, including the Form 3L, Form 3BL, as well as their new Form 4, Form 4B, Form 4L and Form 4BL. Along with their advanced 3D printing materials, which are readily available for next-day delivery. To complement their printers, we also stock the essential post-processing units, such as the Form Wash and Form Cure for the Form Series, and the Fuse Sift for the Fuse Series.

Formlabs: Pioneering Modern 3D Printing Solutions

- Founded in 2011, Massachusetts-based Formlabs is a prominent 3D printer manufacturer.

- Leading players in Desktop-Class Stereolithography (SLA) 3D Printing.

- They specialise in delivering high-quality additive manufacturing solutions for the desktop.

- They maintain a strong commitment to innovation, continuous research, and development.

Superior Print Resolution with Technology-Driven Hardware

- Formlabs has pioneered the use of Low Force Stereolithography (LFS) technology for superior print resolution.

- The Form 4 and Form 4L models are versatile, perfect for applications including prototyping, model-making, and product design.

- The printers can handle a wide range of materials with diverse properties, such as elasticity, flexibility, high temperature resistance, durability, and toughness.

- Formlabs’ technology enables the consistent and efficient production of industrial-grade parts.

- Fuse 1 brings industrial-grade Selective Laser Sintering (SLS) 3D printing to your desktop, ideal for end-use parts and functional prototypes.

- This printer utilises powder-based printing techniques that remove the need for supports, producing accurate parts with excellent mechanical properties.

- Post-print processing is simple with the Fuse 1, ensuring smooth finishing and easy post-processing.

- Compared to traditional industrial SLS systems, the Fuse 1 provides an affordable and cost-effective solution.

Maximise Productivity with Intuitive Software

- Formlabs’ proprietary PreForm and Dashboard software give users greater control and productivity in their 3D printing processes.

- The software features cloud-based access and comprehensive print management tools for efficient workflow.

- Users can monitor print progress and printer status in real-time, optimising productivity.

- Formlabs’ software facilitates effective team collaboration and sends notifications upon print completion.

- The software helps to maximise printer usage and minimise downtime with efficient scheduling and print job management.

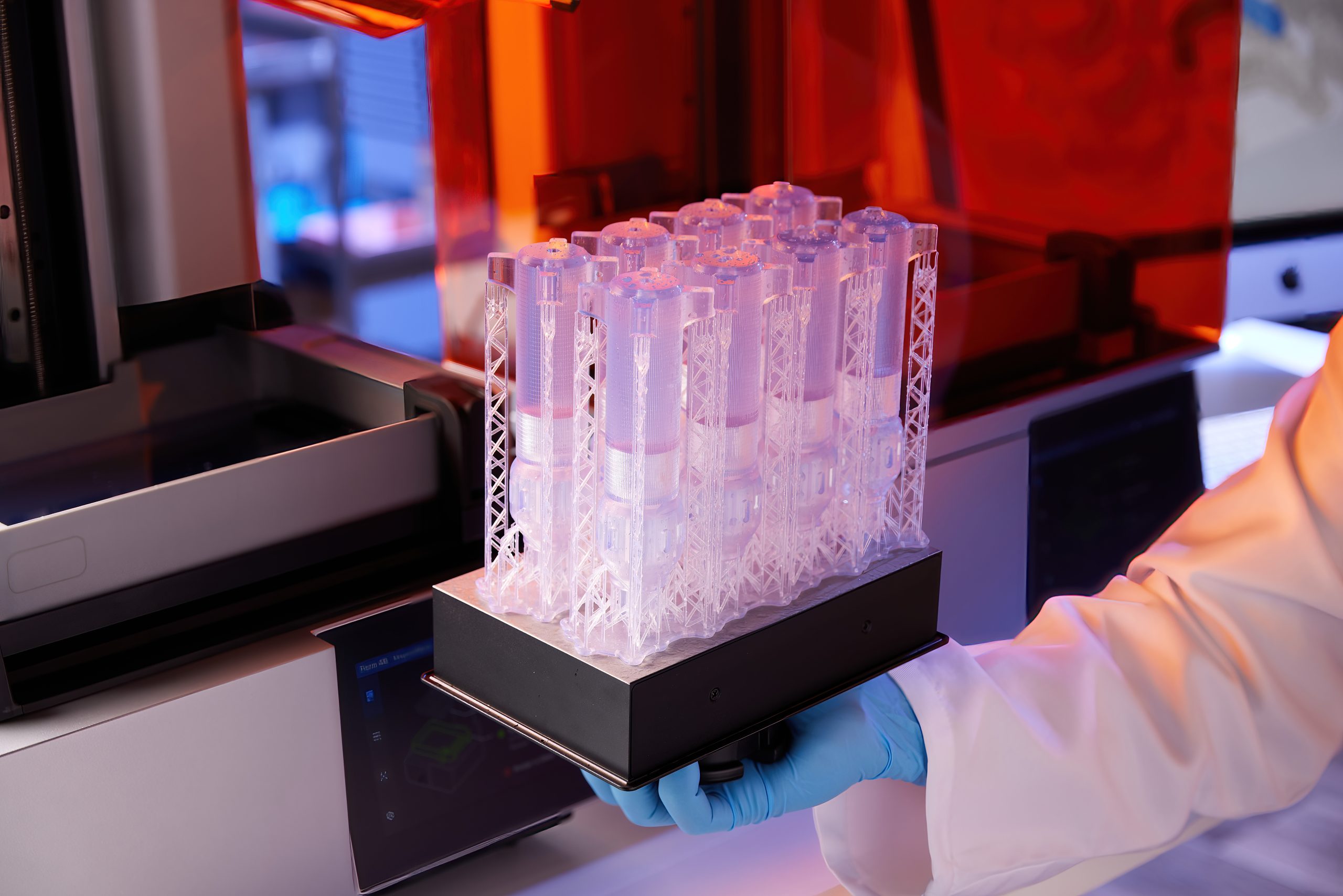

Automated Post-Processing for Flawless Finishes

- Formlabs’ Form Wash and Form Cure machines provide automated post-processing solutions, optimising the end-to-end 3D printing workflow.

- Custom settings maximise material performance and ensure consistent dimensional accuracy for each Formlabs material.

- The post-processing machines make biocompatibility compliance effortless with push-button operation for every material.

- The end result is a perfect, flawless finish for your 3D printed parts every time.

The Formlabs Form and Fuse series of 3D printers have a huge range of potential applications across industries like engineering, design, research, medicine, dentistry, art, and many others. Formlabs’ printers are built for creatives who want to make consistent, high resolution parts and models.

Additive-X | Your Formlabs PLATINUM UK Partner

Order or Request a Quote

Additive-X stock the full range of Formlabs printers, materials and options for next-business-day delivery

3D Printing from Formlabs Printer Range

Formlabs Form 4L

Formlabs Form 4BL

Formlabs Form 4B

Formlabs Fuse 1+ 30W

Formlabs Form Auto

Formlabs Fuse Blast

Formlabs Form Wash (2nd Generation)

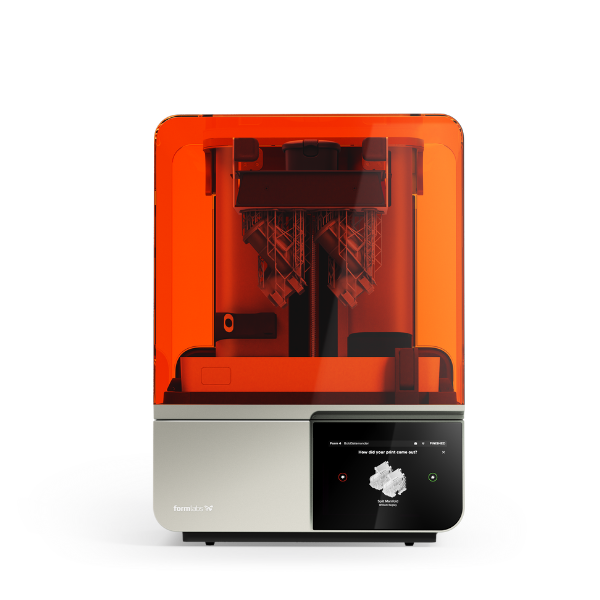

Formlabs Form 4

Industrial Parts at Blazing Speeds

Technology: LFD

Build Volume: 20 x 12.5 x 21 cm

Minimum Layer Resolution: 25-300μm

Cost of Machine: Starting at £3,699

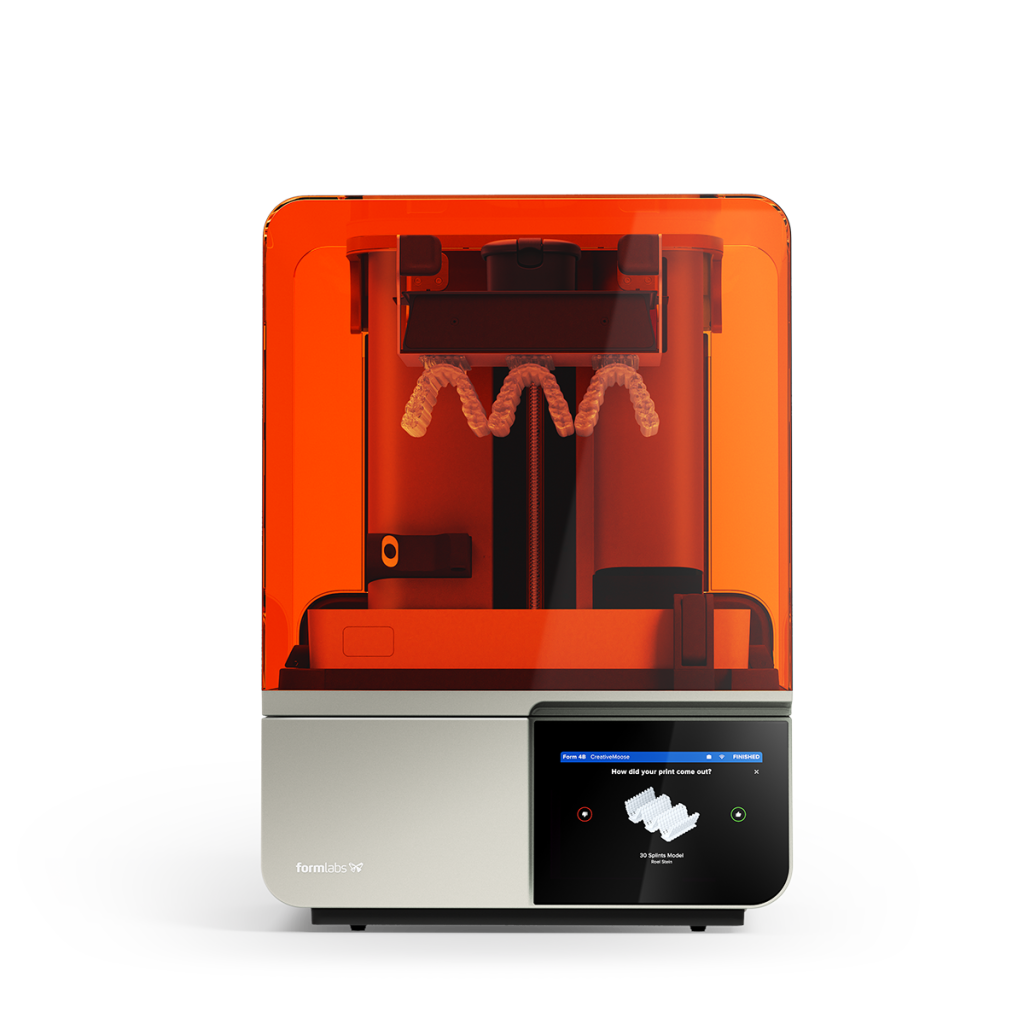

Formlabs Form 4B

Desktop Resin 3D Printer

Technology: LFD

Build Volume: 20 x 12.5 x 21 cm

Minimum Layer Resolution: 25-300μm

Opensource: Yes

Cost of Machine: Starting at £5,149

Formlabs Form 4L

Large Format Desktop Resin 3D Printer

Technology: LFD

Build Volume: 35.3 x 19.6 x 35 cm

Minimum Layer Resolution: 25-200μm

Print Speed: 80 mm/h

Opensource: Yes

Cost of Machine: Starting at £7,999

Formlabs Fuse 1+30W

Designed for maximum output and minimum waste, Fuse 1+ 30W is a compact SLS 3D printer

Technology: SLS

Build Volume: 16.5 x 16.5 x 30 cm

Minimum Layer Resolution: 110μm

Materials Available: Nylon 12, Nylon 12 GF and Nylon 11 and Nylon 11 CF

Opensource: No

Cost of Machine: Starting at £22,599

Formlabs Form 4BL

Large Resin 3D Printer for Healthcare applications

Technology: LFD

Build Volume: 14.5 x 14.5 x 18.5 cm

Minimum Layer Resolution: 25-300μm

Print Speeds: 80 mm/h

Opensource: No

Cost of Machine: Starting at £11,299

Formlabs Form Wash

For automated cleaning of parts printed on your Desktop SLA/LFD Printers

Technology: Washing with IPA, TPM or Water

Bucket Volume: 8.6 litres

Maximum Part Size 14.5 x 14.5 x 17.5 cm

Approx Wash Time: 15 minutes with fresh isopropyl alcohol (IPA)

Prints per IPA refill: Approx 70 in regular use

Cost of Machine: £579

Formlabs Form Cure

High-Intensity, Fast Post-curing for 3D printed parts from your Form 3+, Form 3B+, Form 2

Technology: LED-light curing with 13 multi-directional LEDs

Maximum Part Size 14.5 × 14.5 × 17.5 cm

Heat: Precise heat control up to 80 c

Cost of Machine: £640

Formlabs Form Auto

Form Auto is a hardware extension to Form 3, 3B, 3+ and 3B+ that automatically removes finished parts from the build platform.

Technology: SLA

Materials Available: Dental Range, BioMed Clear/Amber, Standard, Draft, Grey Pro, Rigid, Tough & Durable, Flexible & Elastic, Specialty and Jewellery

Opensource: No

Cost of Machine: £2,999

Printing Examples

Want to explore Formlabs solutions and ask about our offers?

Contact our team of friendly Formlabs fans now

01765 694 007

User Stories

3D Printing Architecture: Efficient Prototyping and Iterative Design

3D Printing Architecture: Efficient Prototyping and Iterative Design

How MAG Orthotics have Adopted 3D Printing to Save Time and Resources

Clinical Case Study: Formlabs Temporary CB Resin

Formlabs Dental Sets the New Standard of Dental Practice Care

Fabricating Clear Aligners in a Private Orthodontic Practice

Watch Videos to find out more

Formlabs Form 4 Introduction Video

Introducing the Formlabs Form 4L!

Meet the Fuse 1 high-performance SLS 3D Printer

Rapid Prototyping with Formlabs

Form 4 vs Injection Moulding

3D Printing is all around you

Additive-X | Your Experienced Additive Manufacturing Partner

10+ Years Working With Formlabs • Large UK Stock-holding • 12+ Formlabs Experts

We love Formlabs and 1000s of customers agree with us. Let us help you on your journey to make anything with their SLA and SLS technology.

01765 694 007

News & Blog

Extend the Life of Your Formlabs Resin Printer: Essential Maintenance Tips

Extend the Life of Your Formlabs Resin Printer: Essential Maintenance Tips

Formlabs Resin Printers: What Kind Of Resin Does Formlabs Use?

Understanding the Cost: A Breakdown of the Formlabs Fuse 1+30W Price

Formlabs Fuse 1+30W Materials: Best Options for Quality 3D Printing

Formlabs Fuse 1+30W Print Speed: Boosting Your 3D Printing Efficiency

FAQ’S

Commonly asked questions about Formlabs Form Series and Fuse Series 3D Printers

Post-curing is not required for Standard resins (Black, White, Clear, Grey), instead you can wash and leave the parts to dry in normal UV light. Additive-X recommends post-curing in the Form Cure for all other resins to achieve the mechanical and functional properties as specified on the Formlabs material data sheet.

It depends on a number of factors such as how long the tank has been in contact with resin, which resin you are using, and the geometry of your prints. The good news is your Form 3+/3B+ monitors the % remaining lifetime of the tank for you.

Because the powder contracts after printing, the maximum final build volume is actually 15.92 x 15.92 x 29.55 cm. The printer build volume is 16.5 x 16.5 x 30 cm.