Metal FFF - An Additive Manufacturing Method

Material Ease of Use

High

Facility Requirements Moderate

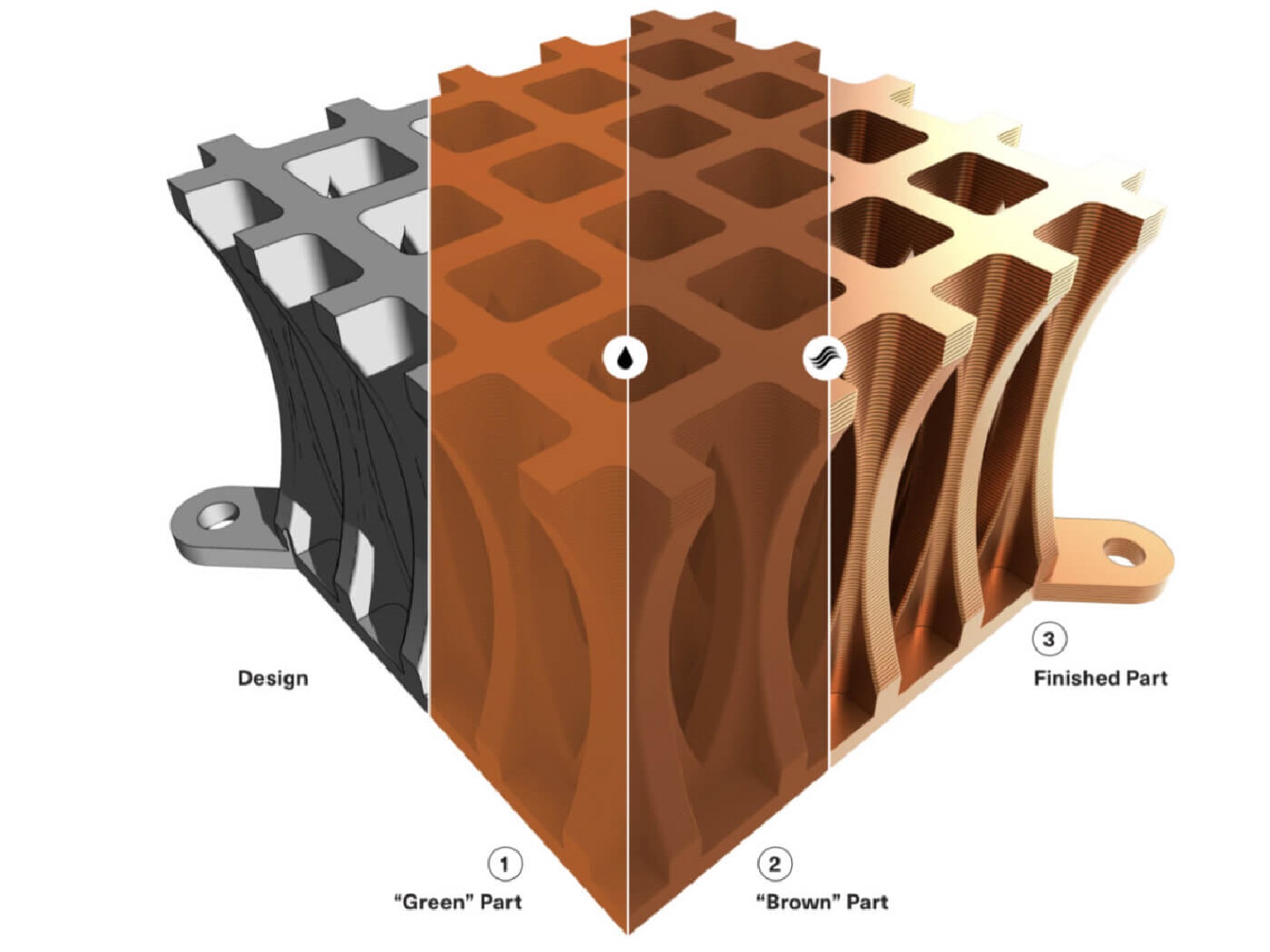

Metal fused filament fabrication (metal FFF) is the most easy-to-use and affordable type of metal additive manufacturing technology. In a relatively simple three step process, metal FFF utilises bound metal powder and sintering – a high energy process that turns the 3D printed parts into a fully solid metal.

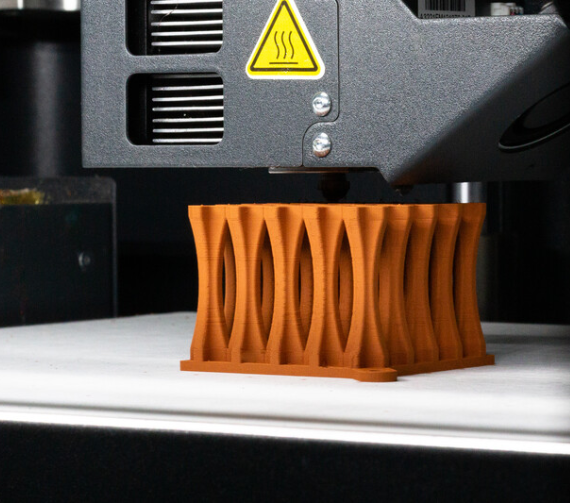

- Step 1 PRINT: metal powder is printed one layer at a time. Parts are scaled up as needed to compensate for the shrinkage during sintering (a later stage).

- Step 2 WASH: after printing a part you have what is called a green part. Green parts are placed into the wash station which uses a de-binding fluid to dissolve the plastic material around the metal powder.

- Step 3 SINTER: after your parts have been washed they are known as brown parts. Brown parts are placed in a furnace where they are heated to burn away remaining binder material and solidify the metal powder.

Why choose metal FFF additive manufacturing?

Interested in metal additive manufacturing?

Want to know if metal FFF is suitable for your application?

Spotlight on applications for Metal FFF

The Metal X 3D printer is part of Markforged’s Digital Forge platform, run on the same Eiger software as the desktop and industrial 3D printers. If you have printed with a Markforged desktop composite printer, you already know how to print on the Metal X! Talk to Additive-X to find out more about applications for metal parts like these:

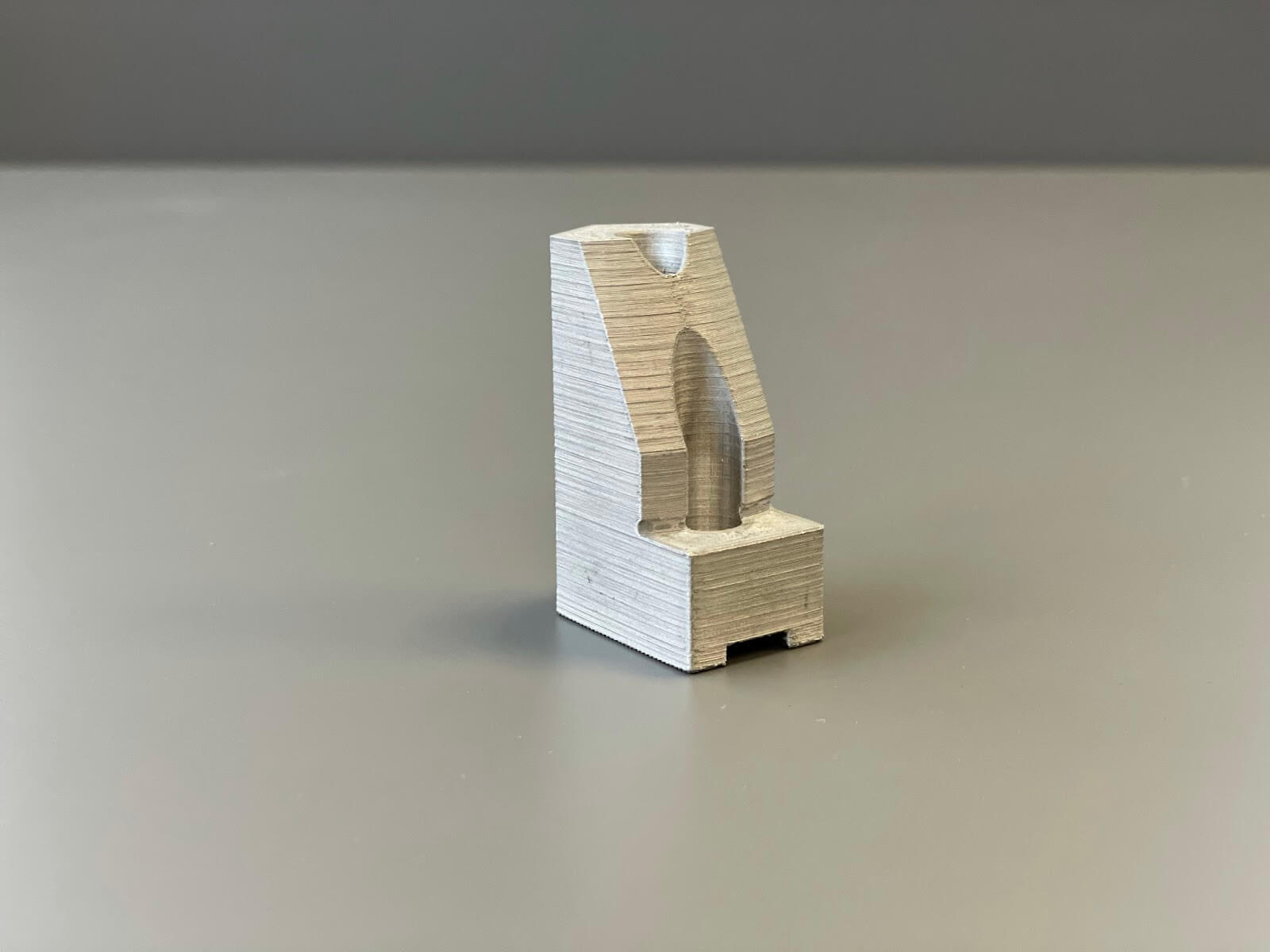

Aircraft Nozzle

17-4 PH Stainless Steel functional prototype for Tecron (Aerospace and Defence)

Bracket Bolting Fixture

17-4 PH Stainless Steel fixture for Nichirin (Automotive)

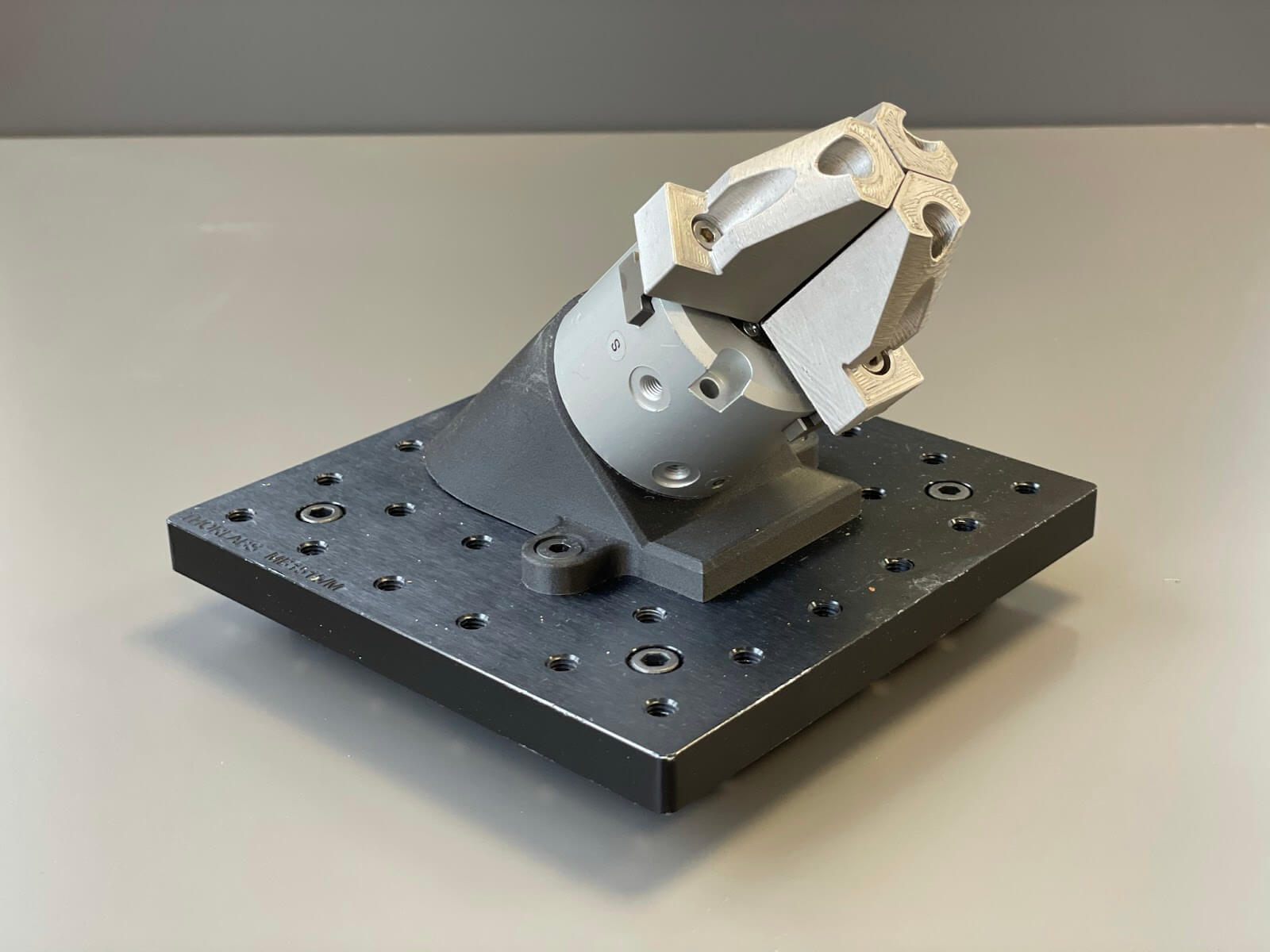

Milling Cutter Body

H13 Tool Steel & Onyx, end-use part for Guhring UK (Manufacturing)

Tool Cooler

Copper tool for Protoypenzentrum GmbH (Manufacturing)

Robotic Gripper Jaws

17-4 PH Stainless Steel gripper jaw for Lean Machine CNC (Manufacturing)

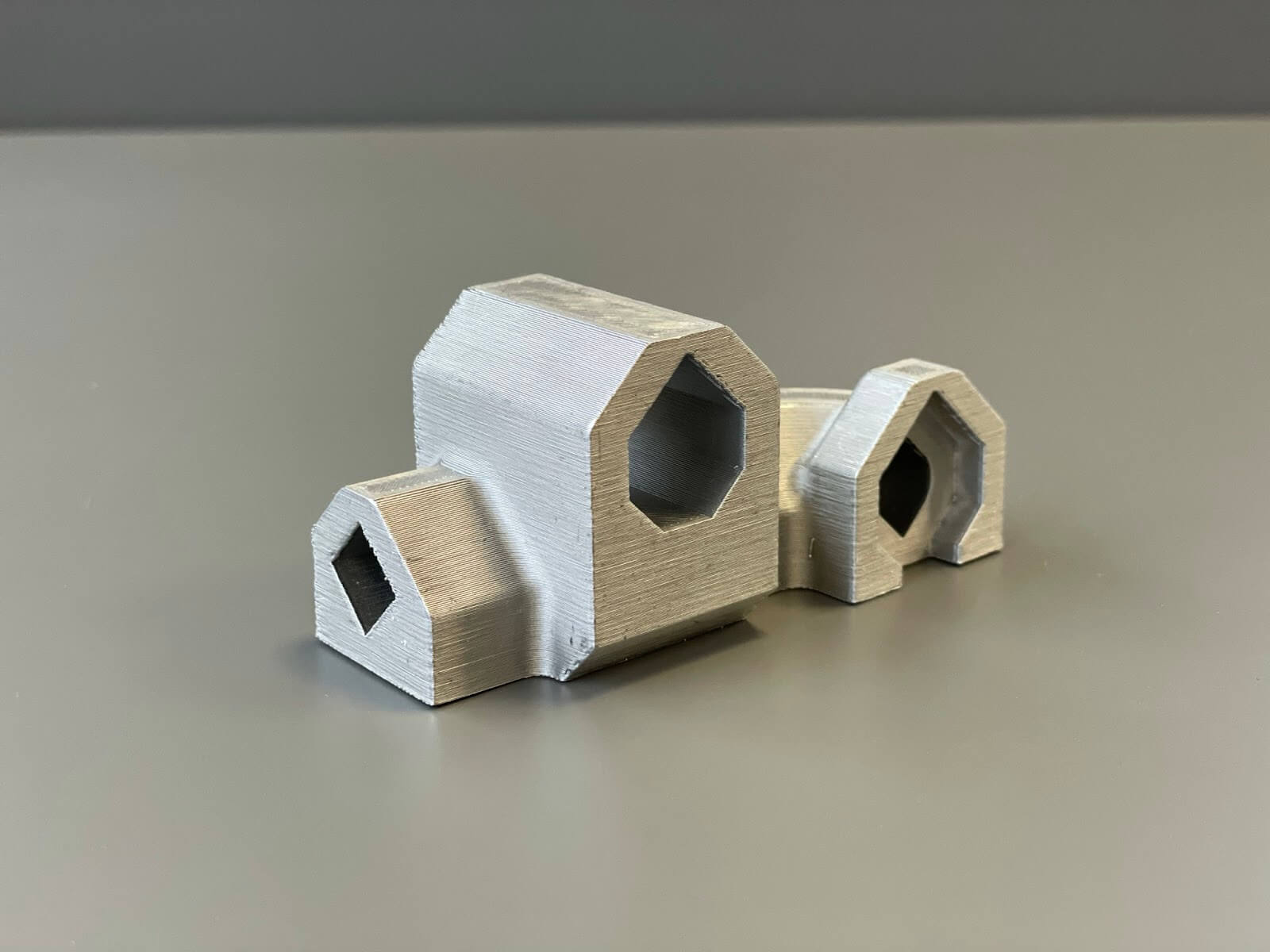

Printing Examples

Metal FFF Printers

Where does 3D Printing fit into your business?

Let Additive-X experts build an additive transformation roadmap for your business

FAQ’S

Commonly asked questions about Metal FFF additive manufacturing

There are 4 things you can do for the best possible printing results

- Identify the critical dimensions

- Maximise contact with the print bed

- Reduce supports

- Think about batch processing

Get in touch with us at Additive-X for a helpful Design Guide for Metal 3D printing which explains what you should do and why