3D Printing Software

Formlabs PreForm

Unlock the full potential of your Formlabs 3D printer with PreForm. This industry-leading software streamlines your workflow by transforming your digital designs into precise, detailed parts on your FormLabs printer.

- Get your printer ready in advance, and initiate print jobs from any location with the convenience of Remote Print

- Generate custom supports and optimize your designs for stable, hassle-free printing

- Make informed printing decisions with real-time previews and fine-tuned settings for the best results

- Remotely monitor your inventory of materials and resin tanks, to ensure the timely replacement of consumables

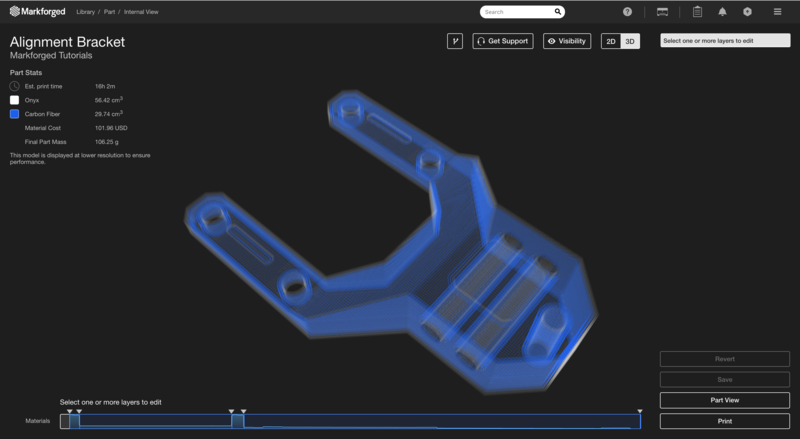

Markforged Eiger

Streamline the journey from design to part with Eiger – the core of Markforged’s Digital Forge. Eiger makes the process of converting your CAD designs into printed metal, continuous fibre, or composite parts as easy as possible.

- Transform your CAD designs into high-quality printed metal, continuous fibre, and composite parts using a seamless and user-friendly interface

- Achieve optimal part performance and maximize manufacturing efficiency by validating print settings on-the-fly

- Automate part scanning to ensure rapid and reliable quality control

- Gain valuable insights into your additive manufacturing through real-time analytics that track key performance indicators

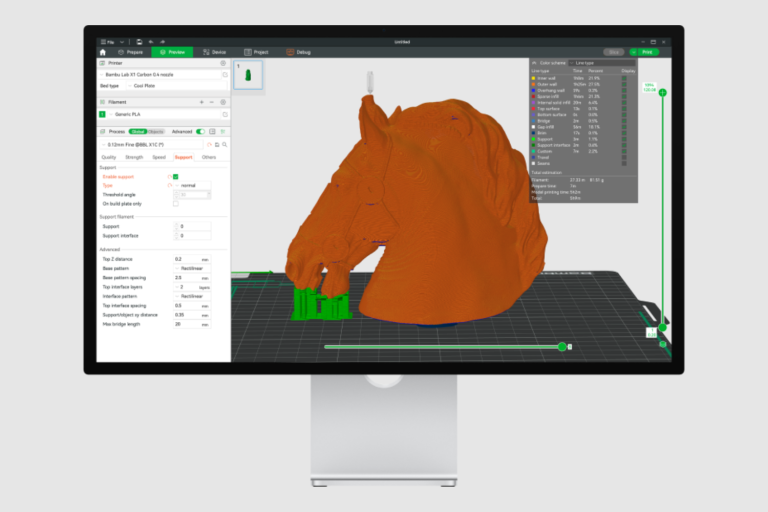

Bambu Lab Studio

Bambu Studio presents cutting-edge slicing software, a comprehensive solution rich in features. With project-based workflows, finely tuned slicing algorithms, and an intuitive graphical interface, our platform ensures users enjoy an effortlessly smooth printing experience.

Key features of Bambu Studio

- Project-based workflow

- High-speed print at quality

- Multi-colour printing

- Remote control and monitoring

- STEP format

- 3D text

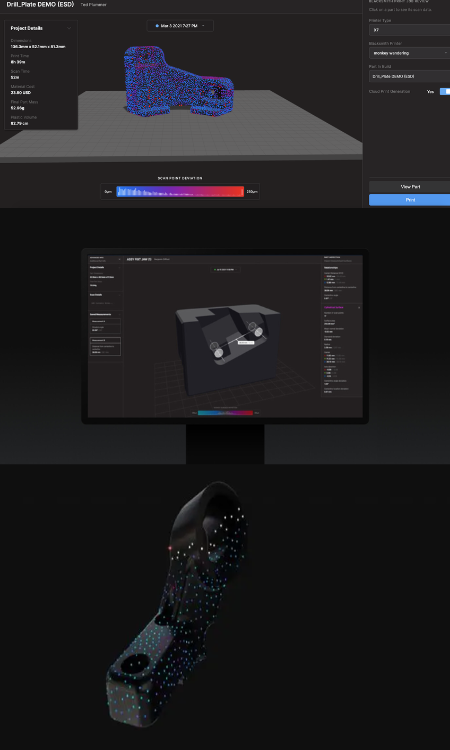

Markforged Blacksmith

Markforged offers a revolutionary tool called Blacksmith: an automated, in-process quality control software for the Markforged Industrial X7 3D printer which lets manufacturers create accurate parts, right from the print bed.

Blacksmith is Markforged’s premium quality control software for their Industrial X7 printer. By scanning, measuring, and comparing dimensional accuracy data of printed parts to their design files, it ensures that manufacturers obtain dependable parts directly from the print bed, guaranteeing reliability and precision.

Blacksmith Process

- Calibrate machine

A series of automated calibration procedures are completed to ensure each printer is operating at the high standards required for Blacksmith.

2. Print & scan part

Blacksmith harnesses the power of the X7’s existing integrated laser micrometer and a patented intelligent scanning process to securely measure parts as they are printed.

3. Compare scan data to STL

Blacksmith collects measurement data during the print and assembles a point cloud review in Eiger. This point cloud is automatically registered and overlaid on the input STL for comparison.

4. Report data

View the deviation across the part’s geometry, and set tolerance limits to assess part quality. The print report is saved in Eiger and can be referenced at any future date.

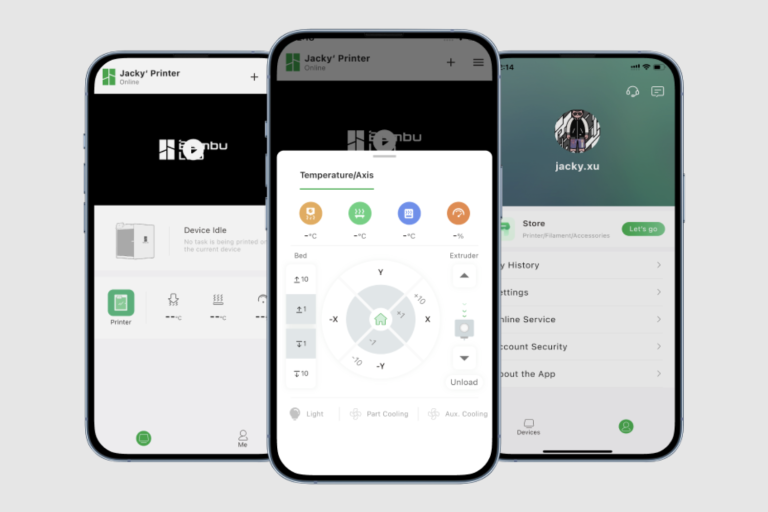

Bambu Handy

Bambu Handy stands as the ultimate all-in-one mobile application crafted exclusively for Bambu Lab 3D printers. With Bambu Handy, you gain complete control over your printer from anywhere, anytime. Experience the convenience of effortless printing at your fingertips.

Key features of Bambu Handy

- Monitor the printing process

- Error checking and reporting

- Manage your printer

- Automatic recording

- Automatic timelapses videos

- Self test program guides