Not all 3D-printed parts require post-processing to become functional, but for the ones that do, AMT™ are here to deliver. AMT provide a suite of post-production processing solutions that enable upscaling of additive manufacturing operations. Their proprietary software and hardware solution, PostPro, permits the automation of these otherwise costly and time-consuming manual processes. Reach your manufacturing end points more easily, and on a greater scale.

Increase output, minimise costs

- AMT offers patented solutions to enhance 3D printing output and offset additional costs.

- Traditional methods of processing printed products can be expensive and inefficient, with up to 60% of a printed part’s cost being attributed to post-processing.

- AMT’s solutions can greatly boost your capacity for end-use part production by automating these typically labour-intensive processes.

Advanced vapour smoothing

- The PostPro SF100, SF50 and SFX are AMT’s next-generation chemical vapour smoothing units that enhance the quality of thermoplastic 3D printed parts.

- Equipped with a 100-litre chamber, the SF100 can quickly and efficiently post-process large parts.

- The PostPro SFX is the first desktop chemical vapour smoothing unit 11 litre build chamber.

- The Surface Finishing (SF) series not only boosts the part’s aesthetic appeal but also improves its mechanical performance by sealing its outer surface. This facilitates easy cleaning, dyeing, and coating.

- After vapour smoothing, parts show less than 0.4% dimensional change and an increase in elongation at break (EAB) scores, with no loss in tensile strength.

- Colour consistency and vibrancy are enhanced by vapour smoothing, and sealing of the outer surface ensures that the parts become both watertight and airtight.

Fully automated de-powdering

- AMT’s PostPro range of de-powdering (DP) and surface blasting (SB) systems significantly speed up the process of gently yet effectively cleaning your printed parts and enhancing the surface finish.

- De-powdering uses compressed air and a media such as glass beads to remove residual powder without damaging fine details on a printed part.

- Parts which have been depowdered and surface blasted can then also go through the vapour smoothing process for a smoother finish and seal

- All units come with a touchscreen HMI unit for adjusting part parameters and programming recipes.

- Find the optimal settings for blasting your parts, save them, and then reuse them repeatedly.

- All of the PostPro DP systems are printer material agnostic, meaning they work with all powder-based printer platforms.

- The range encompasses DPX, DP/SB Studio, DP/SB, DP/SB Pro, DP/SB Max and DUO Max. also includes a dedicated manual blasting area that facilitates quick blasting of large parts while maintaining the automation settings.

Additive-X | Your AMT Exclusive UK Solution Partner

Want to explore AMT's post-processing solutions?

Talk to one of our AMT experts at a time that suits you.

Post Processing Range

AMT PostPro SF100

AMT PostPro DP

AMT PostPro DP PRO

AMT PostPro DP MAX

AMT PostPro SFX

This remarkable system redefines the future of surface finishing with its innovative approach and cutting-edge green chemistry, PostPro Pure.

Technology: Chemical Vapour Smoothing

Power Chamber Volume: 11.5 Litres

Printer Compatibility: SLS, MJF, CFR, FFF/FDM, FGF, HSE, HSS

Footprint: 450 x 500 x 845 mm

Cost of Machine: Price on request

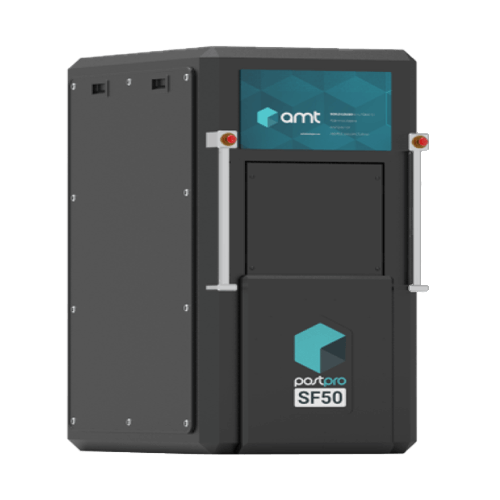

AMT PostPro SF50

Fully automated vapour smoothing technology that smooths and seals thermoplastic 3D printed parts.

Technology: Chemical Vapour Smoothing

Process Chamber: 400 x 300 x 400 mm (48 litres)

Printer Compatibility: SLS, MJF, CFR, FFF/FDM, FGF, HSE, HSS

Material Compatibility: PA6, PA11, PA12, ABS, PC, PP, TPU, TPE, SBC, PEBA, Glass/Carbon/Mineral – filled

Footprint: 830 x 1,400 x 1830 mm

Cost of Machine: Price on request

AMT PostPro SF100

Larger volume solution, fully automated vapour smoothing technology that smooths and seals thermoplastic 3D printed parts.

Technology: Chemical Vapour Smoothing

Process Chamber: 400 x 600 x 400 mm (96 litres)

Printer Compatibility: SLS, MJF, CFR, FFF/FDM, FGF, HSE, HSS

Material Compatibility: PA6, PA11, PA12, ABS, PC, PP, TPU, TPE, SBC, PEBA, Glass/Carbon/Mineral – filled

Footprint: 830 x 1,400 x 1830 mm

Cost of Machine: Price on request

AMT PostPro DP

Affordable, automated 2-in-1 de-powdering and shot blast cleaning system for low volume production.

Technology: Depowdering and shot blasting

Max Load: 15 kg

Printer Compatibility: SLS, MJF, CFR, FFF/FDM, FGF, HSE, HSS

Blast Media: Glass beads, polybeads, corundum, ceramics, nut shells, plastics, fine sized stainless steel and steel

Footprint: 1,626 x 1,600 2,206 mm

Cost of Machine: Price on request

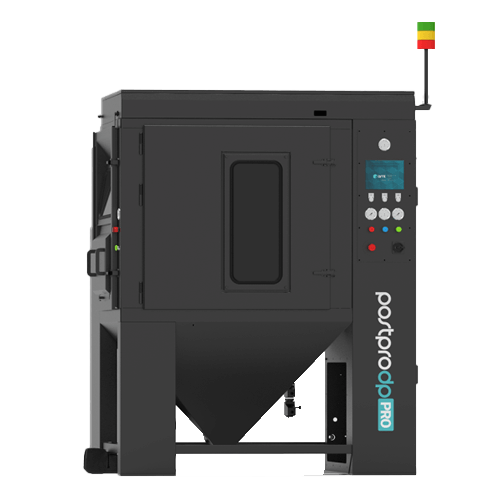

AMT PostPro DP Pro

Fully automated, affordable 2-in-1 de-powdering and shot blast cleaning system with 2 blast guns for higher volume production.

Technology: Depowdering and shot blasting

Max Load: 20 kg

Printer Compatibility: SLS, MJF, CFR, FFF/FDM, FGF, HSE, HSS

Blast Media: Glass beads, polybeads, corundum, ceramics, nut shells, plastics, fine sized stainless steel and steel

Footprint: 1,700 x 1,800 x 2,500 mm

Cost of Machine: Price on request

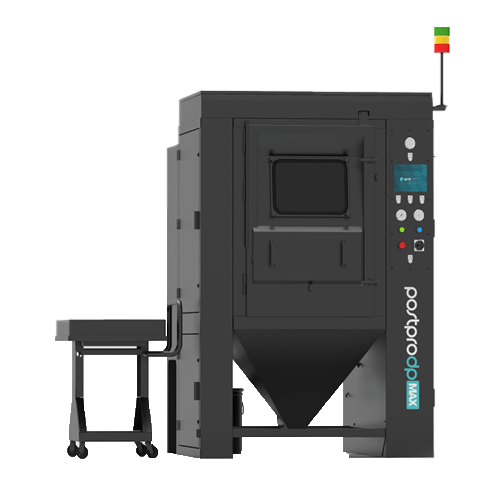

AMT PostPro DP Max

Fully automated, affordable 2-in-1 de-powdering and shot blast cleaning system for maximum throughput, includes 3 blast guns.

Technology: Depowdering and shot blasting

Max Load: 30 kg

Printer Compatibility: SLS, MJF, CFR, FFF/FDM, FGF, HSE, HSS

Blast Media: Glass beads, polybeads, corundum, ceramics, nut shells, plastics, fine sized stainless steel and steel

Footprint: 1,617 x 1,760 x 2,506 mm

Cost of Machine: Price on request

Post-Processing Examples (Before & After)

Advice for All Industries & Experience Levels

Speak to one of our experts about post-processing solutions.

Case Studies

Post-Processing Videos

AMT general video

AMT post processing technology

AMT Repeatability video

Additive-X | Your Experienced Additive Manufacturing Partner

Post-Processing as a service • Impartial Advice & Support • Demos and samples

Additive-X understands the importance of post-processing solutions for achieving your larger-scale digital manufacturing goals.

FAQ’S

Commonly asked questions about AMT Post-Processing Solutions

3Dprinted parts from all technologies, with the exception of SLA.

It smooths and seals the surface of the 3D printed parts, achieving an injection-moulded look and feel. In addition the process allows you to smooth complex geometries and internal cavities of thermoplastic parts without degrading the mechanical properties.

Speeds up production. The machines gently clean large batches of parts in less than 10 minutes and with the ability to store basket angles and recipes you can achieve reliable, repeatable results ensuring maximum output.