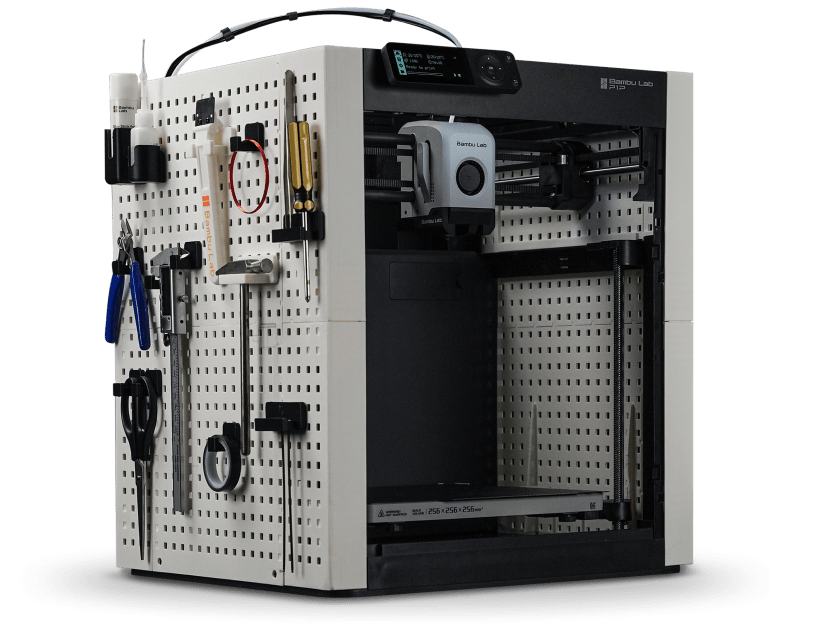

Swapping filaments is a regular part of your 3D printing workflow that you must master for consistent, high-quality prints with your Bambu P1P printer.

You’ll find yourself changing filaments when switching between materials like PLA, PETG HF, TPU HF, and PVA, each offering unique properties for different printing requirements.

Whether you’re reaching the end of a spool or want to introduce a new colour to your project, knowing the correct procedure ensures smooth transitions and optimal print quality.

Join us below for a complete guide.

Replace your filament in four steps

- Press ‘Unload’ on your Bambu P1P’s touchscreen and wait for the hot end to heat up. Don’t pull the filament yet – your printer needs time to reach the right temperature.

- Let your P1P cut the filament automatically when it reaches the right temperature. Keep an eye on the screen as it shows the current temperature and guides you through the following steps.

- Pull out the old filament gently when your P1P’s display, Bambu Studio, or Handy app tells you to. If the filament sticks, hit ‘Retry’, and your printer will reheat and try the removal process again.

- Load your new filament by pushing it into the feeding mechanism until it clicks into place at the extruder entrance. Watch your screen and follow each prompt as your printer pulls the new filament through.

This video will also help:

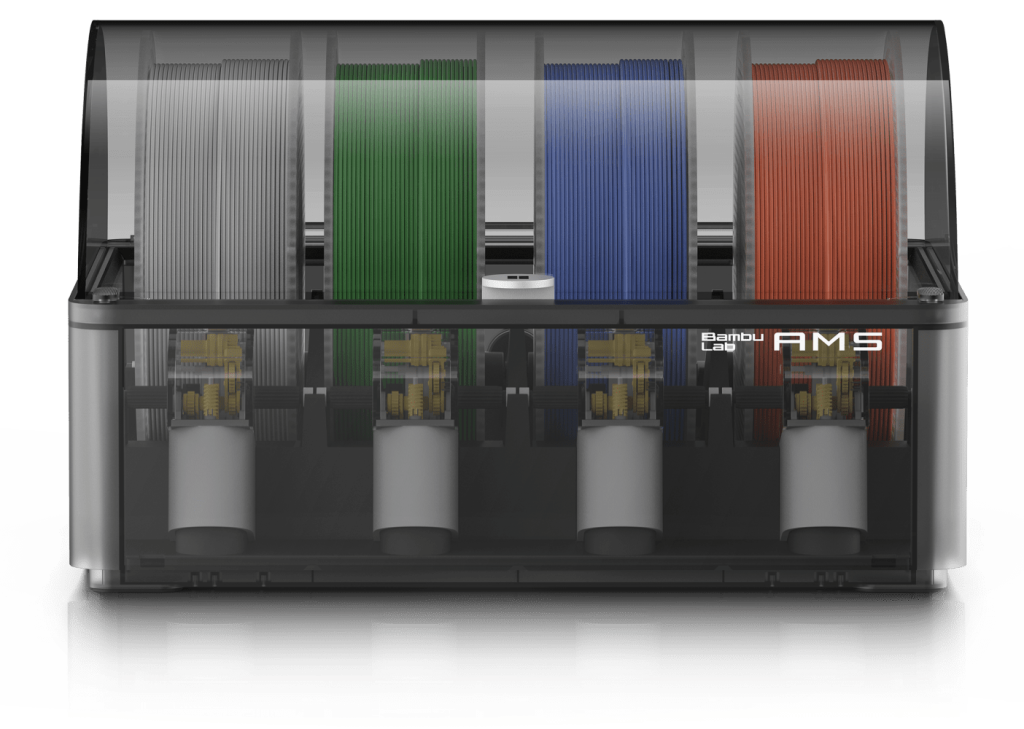

Upgrading to AMS

The Automatic Material System transforms your filament management experience by eliminating manual spool changes and print interruptions.

Your AMS monitors filament tension and feed rates through intelligent sensors, automatically transitioning between spools when needed during multi-material prints.

The system’s active monitoring prevents common issues like filament tangles and ensures consistent material flow throughout your printing process.

P1P capabilities

Your Bambu P1P has advanced features that complement its filament handling capabilities, including precise automatic bed levelling for perfect first layers.

The printer’s motion control system delivers impressive speeds up to 500 mm/s while maintaining exceptional print quality through active vibration compensation.

These features ensure consistent extrusion and layer adhesion, regardless of your chosen filament type.

Making the choice

The Bambu P1P offers straightforward filament changes, whether operating manually or with the AMS system.

The manual process is quick and intuitive, while the AMS upgrade provides complete automation for uninterrupted printing.

Your overall printing volume and how frequently you switch between different materials should sway your choice. The AMS is fantastic if you print multiple colours and filaments. The manual option suits less frequent changes. Can’t decide which is best for you? Our team is here to help. Call 01765 694 007.