High Temp Resin is an advanced engineering material designed by Formlabs for 3D printing applications that require exceptional heat resistance.

This specialised resin stands out in the Formlabs material lineup because it is remarkable at maintaining structural integrity under high temperatures.

Unlike standard resins, High Temp Resin offers the highest heat deflection temperature among Formlabs materials. It is a critical solution for engineers and designers working with components that must withstand extreme thermal conditions.

Products:

- Formlabs High-Temp Resin (Form 4)

- Formlabs High-Temp Resin (Form 3)

- Formlabs High Temp Resin (Form 3, Form 4) 5L – use with Resin Pump

Applications: Where High Temp Resin Excels

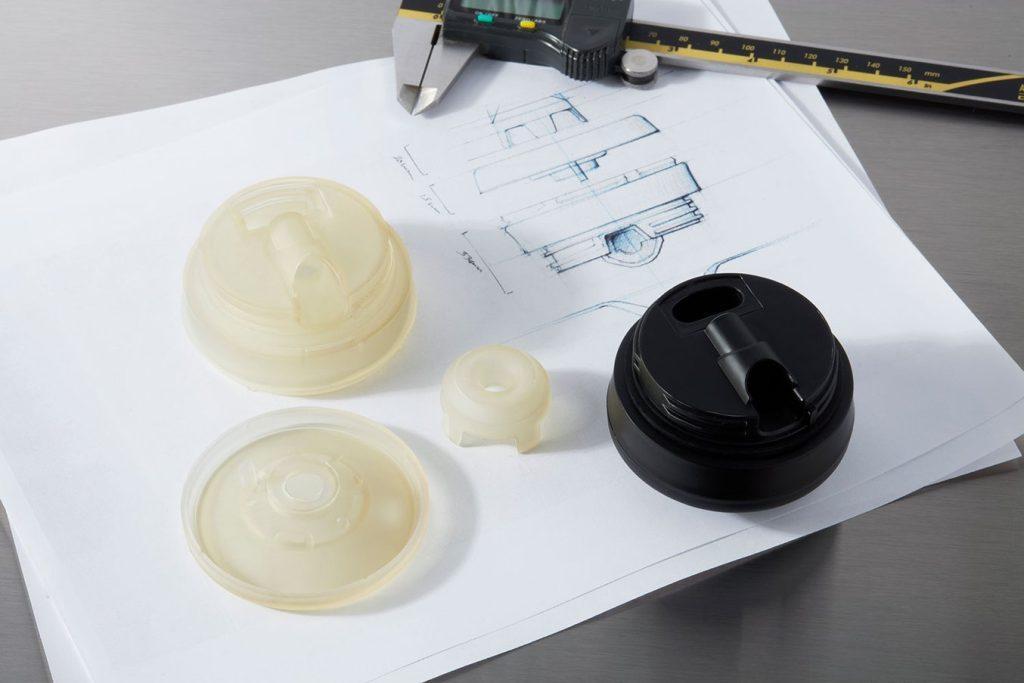

High-temp Resin is ideal for a wide range of demanding applications that require superior thermal stability. It’s ideally suited for creating heat-resistant mounts, housings, and fixtures that must perform in challenging thermal environments.

Industries such as aerospace, automotive, and manufacturing can benefit from this material’s unique properties.

Related: Formlabs Form 4: What is the strongest compatible resin?

Specific applications include designing components for hot air, gas, and fluid flow systems, creating moulds and inserts that can withstand high temperatures, and developing parts for vulcanisation processes.

The resin is particularly useful when you need a part that maintains its structural integrity and dimensional stability under significant heat stress.

However, it’s important to note that this resin isn’t suitable for injection moulding with industrial equipment, parts under heavy load, or applications requiring flexible components like snap-fits.

How to Use High Temp Resin

Preparation and Printing

You’ll need to follow some specific guidelines when preparing to print with High Temp Resin. First, ensure you use a compatible resin tank, as this material requires a higher peel force during printing.

The resin prints three-layer heights: 25, 50, and 100 microns. For best results, reserve the 25-micron setting only for small objects, such as jewellery-sized pieces.

Always use PreForm software to prepare your model. When setting up your print:

- Select the specific High Temp Resin version

- Choose your desired layer thickness

- Carefully orient your model to preserve fine details

- Generate support for your print

- Remember that supports are crucial – avoid printing High Temp parts directly on the build platform because adhesion issues can occur between the part and the build platform surface

Washing and Post-Processing

After printing, your post-processing steps are critical. Use Form Wash for cleaning, but be cautious:

- Wash parts for a maximum of 6 minutes in isopropyl alcohol (IPA) – longer washing times may cause the part to absorb IPA

- If using a Finish Kit, wash in the first bucket for 5 minutes, then transfer to a second, cleaner bucket for another 5 minutes

- Allow parts to fully air dry before post-curing – If the part is not allowed to dry thoroughly, it may crack with exposure to light and heat during curing.

- Use standard support removal and sanding technique

Related: Formlabs Post-Processing Tips: From Print to Perfection

Post-Curing for Optimal Performance

Post-curing is essential to achieve the material’s optimal mechanical properties and high heat deflection temperature. Formlabs offers multiple post-curing options:

For standard applications that do not require the maximum heat resistance:

- Post-cure in Form Cure for 60 minutes at 60°C

For higher heat resistance (up to 142°c):

- Post-cure parts in Form Cure for 120 minutes at 80°C

For maximum heat resistance (up to 238°c):

- Post-cure parts in Form Cure for 120 minutes at 80°C

- Thermally post-cure in a non-food oven for 3 hours at 160°C

Important Considerations

- Do not mix different versions of High Temp Resin (V1 and V2)

- The material has very low flexibility, so it’s not suitable for parts requiring flex

- Always consult the Technical Data Sheet for specific material properties

- Regularly inspect your resin tank, as High Temp Resin can shorten the tank’s lifespan

Remember that successful 3D printing with High Temp Resin is more about technique than material selection.

Experiment with different post-curing options, carefully orient your models, and always use appropriate supports.

Pay attention to these details and continuously refine your approach to push the boundaries of what’s possible with high-temperature 3D printed components, transforming complex engineering challenges into precise, reliable solutions.