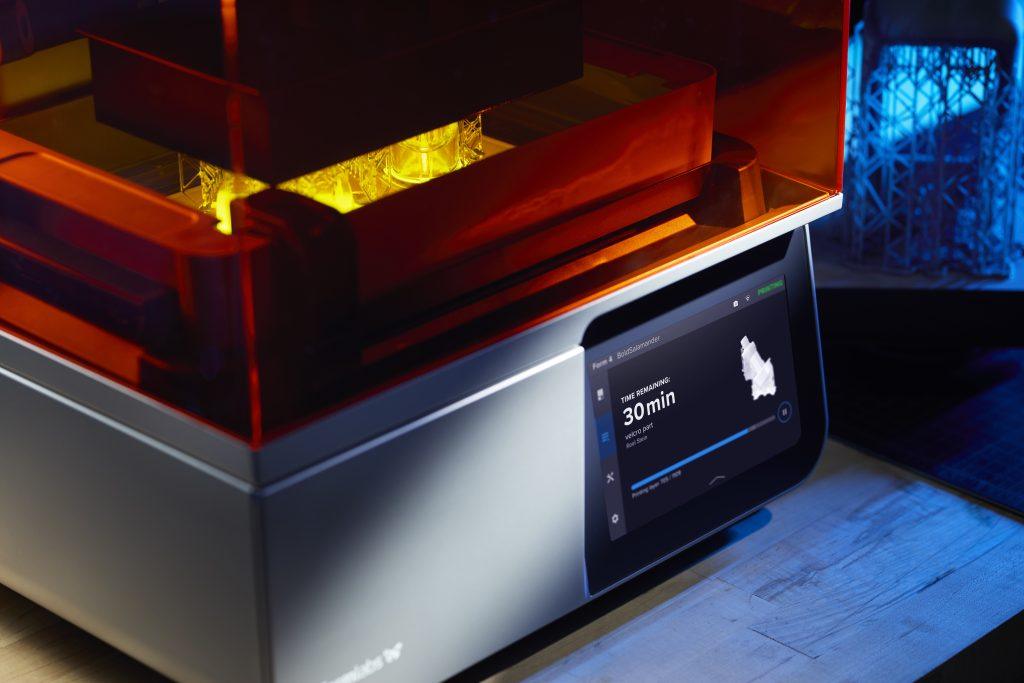

The seamless integration of Formlabs Form 4’s post-processing solutions transforms resin 3D printing from a complex, time-consuming process into an efficient, automated workflow.

Combining Form Wash and Form Cure with your Form 4 printer can achieve consistently superior results while minimising hands-on time.

Related shopping:

- Formlabs Form 4 Complete Package (including Form Wash (Gen 2) and Cure)

- Formlabs Form 4 Premium Package

- Formlabs Form 4 Basic Package

- Formlabs Form Wash (2nd generation)

- Formlabs Form Cure L

Streamlined cleaning with Form Wash

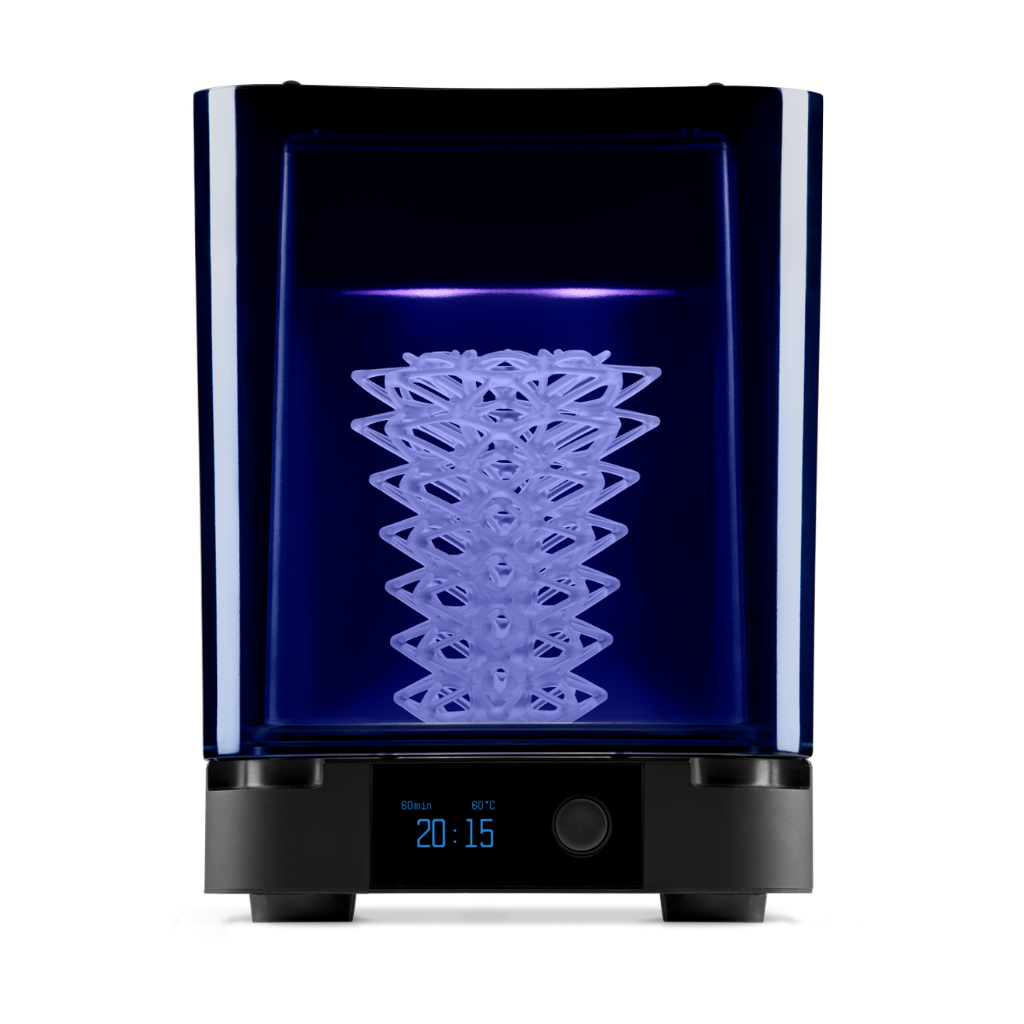

Form Wash revolutionises part cleaning through intelligent automation and improved agitation technology.

The second-generation system delivers 3x more powerful agitation than its predecessor, thoroughly cleaning intricate geometries and hard-to-reach areas. A user selectable low-speed wash program prevents damage to very delicate parts.

An adjustable platform mount system accommodates build platforms from any Formlabs desktop printer, allowing you to transfer parts directly from the printer to the wash station without removal.

The flexible solvent volume system optimises cost efficiency by using only the amount of cleaning solvent needed for your specific parts. Isopropyl alcohol (IPA) is the recommended cleaning solvent but alternatives such as TPM and Formlabs Resin Washing Solution are also compatible with Form Wash.

A single IPA refill supports up to 120 prints, a 67% improvement over previous generations. When washing is complete, parts automatically rise out of the solution for controlled air drying, preventing oversoaking that could impact dimensional accuracy, cause cracking during curing or compromise biocompatibility.

Precision post-curing for optimal properties

Form Cure complements the washing process by delivering precisely controlled post-curing to help parts reach their peak mechanical properties.

Programmable temperature and UV exposure settings for each Formlabs resin eliminate the guesswork of post-curing, helping to ensure your parts achieve their intended strength, durability, and performance.

Integrated workflow advantages

The complete Form 4 ecosystem creates a synchronised workflow where each step seamlessly transitions to the next.

Quick Release Technology on the Build Platform Flex enables rapid part removal while reducing breakage risks. Parts can be moved directly into Form Wash with minimal handling, then proceed to Form Cure with pre-configured material-specific settings.

The system monitors the number of wash cycles, notifying you when maintenance is needed. That predictive approach helps maintain consistent results while minimising waste and optimising resource usage.

A combination of enhanced agitation in Form Wash and precision heating and UV exposure in Form Cure delivers cleaner parts faster, with improved surface finish and material properties.

Maximising productivity through automation

Form Wash’s adaptable platform mounts and automated cleaning cycles eliminate manual handling steps, reducing labour time and potential part damage.

It accommodates varying part sizes and quantities, with flexible solvent volumes from 7 to 15 litres. Validated wash times and agitation patterns ensure optimal cleaning without operator intervention.

Material-specific optimisation

The Formlabs Form 4 ecosystem includes pre-programmed settings for Formlabs’ extensive resin library, ensuring each material achieves optimal properties.

From standard prototyping resins to specialised engineering and biocompatible materials, the post-processing parameters automatically adjust for the best results.

It supports water-washable resins and those requiring IPA, with Form Wash compatible with alternative solvents like TPM.

Quality assurance through controlled processing

Consistent post-processing significantly impacts final part quality. Form Wash’s precision agitation prevents over-cleaning while ensuring complete resin removal.

The automated lifting mechanism eliminates part damage from prolonged solvent exposure. Form Cure’s temperature-controlled environment and calibrated UV exposure deliver repeatable material properties without degradation.

Maintenance and longevity considerations

The 2nd generation of Form Wash includes key durability improvements for sustained heavy use. An integrated monitor tracks cleaning solution usage, displaying alerts when replacement is needed.

The supplied hydrometer measures resin saturation levels helping to maintain optimal cleaning concentration, while the bucket design simplifies routine cleaning and solvent changes.

Setting up automated cleaning cycles with appropriate agitation times prevents overcleaning, protecting your parts and equipment. Regular cleaning of the wash bucket and timely solvent replacement keeps your post-processing results consistent.