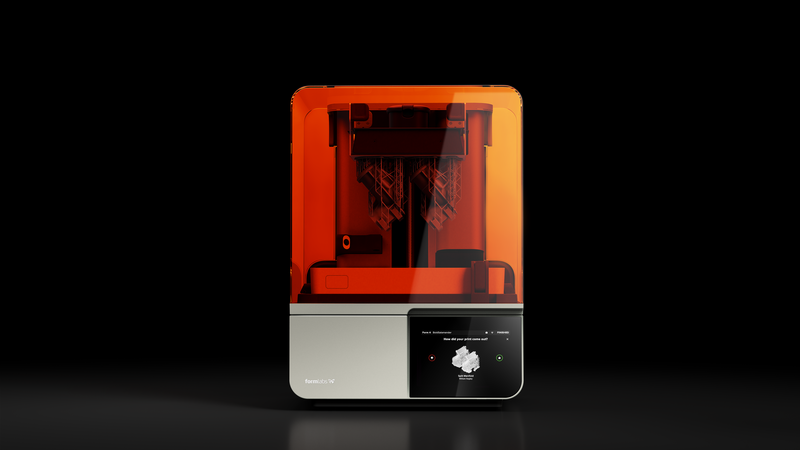

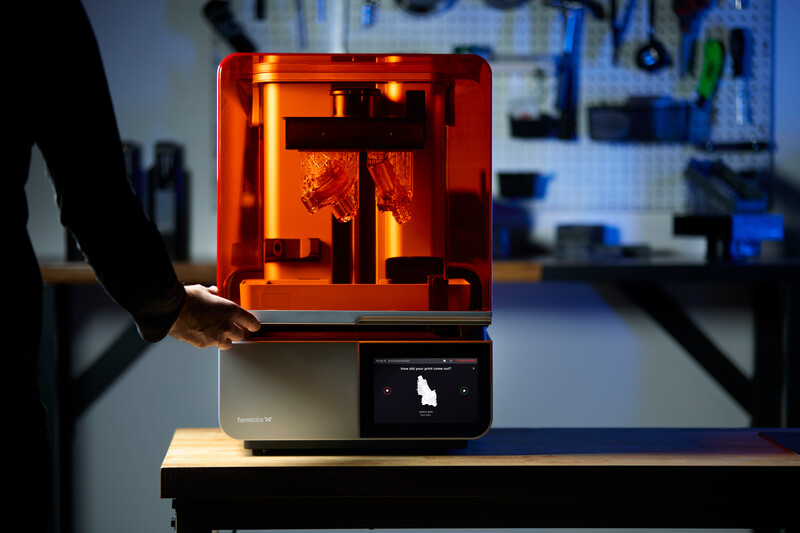

The Formlabs Form 4 Release Day Is Here!

The brand new Form 4 and Form 4B 3D Printers have arrived and our team are excited to share it with you. The new Form 4 Series offers up to x4 faster printing speeds, while vastly improving part quality. So what’s changed, and what’s new for the Form 4?

We’ve broken down everything you need to know below…

Key Features

- New Low Force Display (LFD)

- New Masked SLA Technology (MSLA)

- Blazing Fast Printing Speed

- Improved Reliability

- Versatile Material and Industry Application

Custom LCD and New LFD

The all-new Form 4 and Form 4B have a custom LCD screen as part of a proprietary Low Force Display (LFD) print engine alongside 17 other optical components and a patent-pending release texture on a flexible film tank.

It is a faster and more reliable machine than the Form 3, with LFD delivering higher print quality and better material performance than LFS (Low Force Stereolithography) technology and traditional LCD and SLA 3D printers.

New optical baffle and plano-convex lenses provide highly collimated light, producing sharp details and excellent dimensional accuracy through the LCD.

You’re probably wondering why Formlabs has pivoted away from LFS, which they introduced as an upgrade to SLA in 2019. The answer is they haven’t – the Form 3 is still available – but increasing print speeds with inverted SLA always means a trade-off in print quality, reliability, or material performance, and the LCD solves a large part of that problem.

The LCD works with a high-powered backlight and laser optics to deliver highly controlled and collimated light uniformly across the build plane, helping maintain print accuracy and detail sharpness even at very high print speeds.

The flexible film on the resin tank significantly reduces adhesion forces during the peeling process, enhancing compatibility with a broader range of materials with higher viscosities.

LCD or SLA? What’s the deal?

The Form 4 is not a traditional SLA or LCD printer – it is a new category of masked SLA printer (MSLA) with a Low Force Display (LFD) print engine invented by Formlabs.

You won’t find MSLA technology anywhere else, and most of the unique parts in the Form 4 are in the patent-pending stage of development.

Print Speeds to Gawk At

The LFD print engine in the Form 4 pushes print speeds to the limit of what’s possible without unacceptable trade-offs.

The custom LCD screen finds the ideal balance of light transmission (for curing speed), pixel size (for detail), and optical filtering (for a long lifetime).

Formlabs has paired this with a powerful, highly collimated backlight to maintain precision as light passes through the LCD to cure the resin.

The decision to use a 4K LCD rather than a higher resolution 8K or 12K panel was likely driven by these considerations—while more pixels can theoretically allow finer detail, the smaller pixel size on these ultra-high-res screens often comes at the cost of slower light transmission and, therefore, slower print speeds.

Maximum Reliability

The Light Processing Unit (LPU) is a long-life consumable rated for 600k-2.7M layers, depending on material and layer height.

For the average user, this translates to years of printing before replacement, and the LPU’s robust metal frame, scratch-resistant optical window, and internal debris monitoring help maintain print consistency over this long service life.

The flexible film resin tank minimises peel forces during printing, slashing wear and tear on the tank and helping prevent print failures due to parts sticking to the film.

The lack of a hard lifetime limit on the tanks (for most materials) also means users can keep printing without interruption as long as the tanks remain in good condition.

An integrated resin mixer ensures consistent resin properties throughout the print, reducing the risk of defects or failures due to poorly mixed or settled resin, while optical sensors monitor mixer operation and can pause the print if a problem is detected – perfect if you are in a not-so-well-controlled environment.

Transformative Production

The broad range of engineering and speciality resins available support applications from initial concept models to high-precision functional prototypes and even short-run end-use parts, with draft, professional, and engineering materials available.

Resins like Castable Wax and the upcoming Bluecast X-One V2 (probably shipping by the end of Q3 2024) are perfect for investment casting workflows, allowing jewellers to go from digital design to ready-to-cast parts quickly and accurately.

The Form 4 B’s biocompatible materials and specialised software (PreForm Dental, Scan to Model) are well-suited for dental applications.

Fast Model Resin can rapidly produce orthodontic models for clear aligners and retainers, while Precision Model Resin delivers exceptionally accurate restorative models for implants, crowns, and bridges.

Beyond dentistry, the Form 4B has applications across the healthcare and biomedical industries, where biocompatible resins can create highly accurate anatomical models for surgical planning, patient education, and medical device development.

Summing Up

It’s clear that the Form 4 and Form 4B can achieve faster print speeds compared to laser-based SLA systems, but the real kicker is that they do so while maintaining the high resolution and smooth surfaces that make SLA such a useful tool – few other technologies can compete for surface finish (and now speed too).

As we test the Form 4 and learn its mechanics, its true potential will come to light – and we’ll update this article in kind. Stay tuned.