Markforged offers two distinctive high-performance ranges for composite printing with carbon fibre reinforcement capabilities.

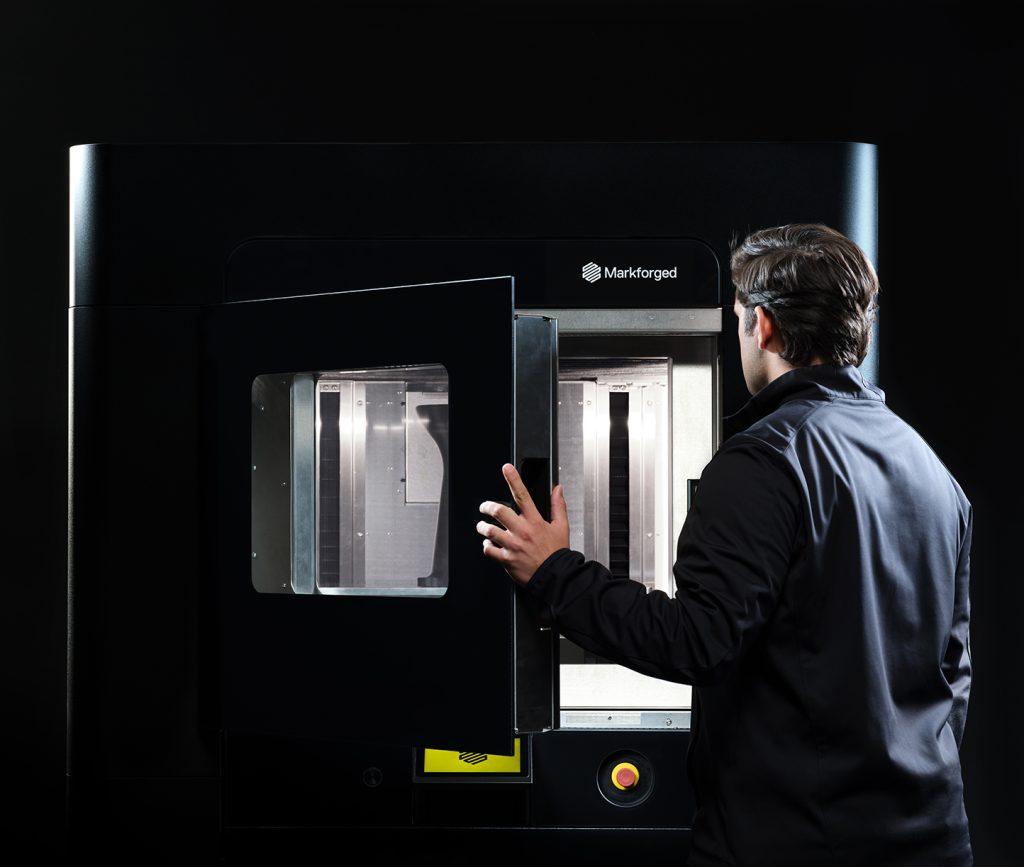

The FX20 serves organisations seeking larger production capacity with aerospace-grade materials, while the X7 targets workshops needing precision parts within space constraints.

Both printers use Fused Filament Fabrication (FFF) as their base technology and reinforce builds with continuous fibre placement.

The printers lay down thermoplastic material and embed unbroken strands of reinforcement fibres within layers to create composite parts stronger than conventional plastics.

Which 3D printer meets your materials, build volume, and production environment requirements? Join us below to find out.

Build volume

FX20

The FX20’s 525 × 400 × 400 mm build volume for single-nozzle operations provides significant production space.

Multi-nozzle builds reduce width slightly to 500 mm while maintaining depth and height dimensions. Factory floors need substantial space for the FX20’s 1325 × 900 × 1925 mm footprint and 530 kg weight.

- Single-nozzle builds: 525 × 400 × 400 mm (20.6 × 15.7 × 15.7 in)

- Multi-nozzle builds: 500 × 400 × 400 mm (19.7 × 15.7 × 15.7 in)

This means that when using multiple nozzles (the FX20 has a direct-drive print head with three nozzles — two plastic, one fibre), the effective build width reduces from 525 mm to 500 mm. The depth and height dimensions remain unchanged at 400 × 400 mm.

X7

Working with 330 × 270 × 200 mm build space proves sufficient for most tools, fixtures, and production parts. Workshop integration is more straightforward with the X7’s modest 584 × 483 × 914 mm dimensions.

We wouldn’t call the X7 portable, but it is easier to relocate than the FX20’s. It weighs 48 kg, allowing deployment across multiple factory locations.

Material capabilities

Markforged FX20

- High-performance materials include ULTEM 9085 filament for aerospace applications requiring flame, smoke, and toxicity certification.

- Vega material provides an additional high-temperature option alongside standard Onyx and Onyx FR / FR-A composites.

- Carbon fibre reinforcement in standard, high-temperature, and flame-retardant versions benefits specialised applications.

Markforged X7

- The X7 prints general-purpose Onyx, flame-retardant Onyx FR, FR-A, ESD-safe Onyx ESD, Nylon White, P-PLA, and flexible S-TPU.

- Reinforcement options for static and moving parts include carbon fibre, flame-retardant carbon fibre, standard fibreglass, high-strength, high-temperature fibreglass, and Kevlar.

Part accuracy and properties

Markforged FX20

Your production maintains +/- 125 µm or +/- 0.0015 mm per mm, whichever measurement is greater. The balance between surface finish and production speed comes from layer heights ranging from 50 μm minimum to 250 μm maximum.

Material selection determines part properties, with continuous fibre providing strength comparable to aluminium when embedded correctly.

Markforged X7

The default print layer height is 100 μm, with options ranging from 50 μm for fine detail to 250 μm for rapid production.

Continuous carbon fibre enables parts to reach 800 MPa tensile strength—2.6 times stronger than 6061-T6 aluminium. Weight advantages remain while the tensile modulus reaches 60 GPa, approaching aluminium stiffness.

Software and connectivity

Markforged FX20

Print management happens through Eiger software, which has secure digital library functionality and comprehensive slicing tools.

Two-factor authentication, organisational admin controls, single sign-on integration, and encrypted, tamper-resistant print files enhance security. Ethernet connections facilitate over-the-air updates to maintain current firmware.

Markforged X7

Cloud-based Eiger software provides core functionality matching the FX20 implementation. Wireless operation in workshop environments comes through Wi-Fi connectivity using 2.4 GHz 802.11 b/g/n standards.

The optional Blacksmith adaptive manufacturing technology makes dimensional accuracy verification against design requirements possible.

Application suitability

FX20

Organisations benefit most from mission-critical parts requiring aerospace certification or high-temperature resistance in large formats.

Enterprise-scale production environments replace long-lead machined components with composites. Tamper-proof file distribution and consistent part properties support global manufacturing standardisation.

X7

The X7 system suits manufacturing jigs, fixture components, tooling elements, and end-use parts requiring strength beyond traditional plastics.

Its more compact size and standard power requirements integrate well with workshop environments. Strength exceeding machined aluminium while reducing procurement lead times and costs address production needs.

Price and availability

FX20

The FX20 is available in one version and requires a price on request.

X7

The X7 is available as a standalone printer and in three additional versions:

Markforged X7 Digital Forge Industrial Quality Solution (price on request)

The Markforged X7 Digital Forge Industrial Quality Solution combines the X7 with Blacksmith quality validation software, materials, comprehensive support, and training to ensure accurate parts production and maximise manufacturing efficiency.

Markforged X7 Digital Forge Industrial Fleet Solution (price on request)

The Markforged X7 Digital Forge Industrial Fleet Solution expands on the previous offering with two Mark Two Desktop Printers, creating a complete printing ecosystem with materials, Blacksmith quality validation software, success plan support, and training for multiple team members across the organisation.

Markforged X7 Field Edition (price on request)

The X7 Field Edition packages the X7 printer in a rugged Pelican case with all materials and tools needed for immediate printing in remote locations without regular supply access. Setup takes under three minutes, making it ideal for military and field operations.

Find out more

Contact the Additive-X team for help and advice on choosing the most suitable Markforged printer. Call 01765 694 007, live chat with us, or email [email protected].