Many 3D printers lay claim to being ‘industrial-grade’ but when you delve into their material list, rarely do you find anything more durable than nylon.

That’s where Markforged 3D printers differ. In the case of the Desktop and Industrial series 3D printers, these use nylon or Onyx as the base material (Onyx is a proprietary filament made by Markforged, it’s part nylon, part chopped carbon fibre). You can then reinforce prints with continuous strands of a stronger composite - carbon fibre, fibreglass, or Kevlar - to create truly industrial-grade prototypes and end-use parts.

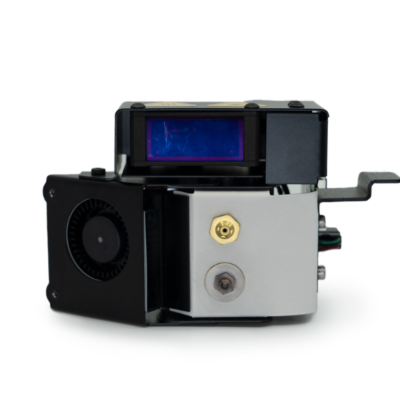

Most Markforged 3D Printers use a technology called Continuous Fibre Reinforcement (CFR). It is Markforged's unique process for reinforcing FFF parts with high-strength continuous fibres. With Markforged's CFR you can quickly 3D print complex parts using materials that are strong, heat-resistant, and chemical-resistant.For example, parts printed in carbon fibre are stronger than 6061-T6 aluminium. The Markforged 3D printer range consists of the desktop series, the industrial series and the Markforged Metal X. The Desktop series includes the Mark Two, Onyx One and Onyx Pro, these machines dependable user-friendly printers. Precision parts with smooth surface finishing. Compatible with standard printing materials. The Industrial series includes the X7, X5, FX10 and their biggest 3D printer the FX20. The industrial grade machines have large build areas and in-chamber sensors for peak performance optimization. Achieve unparalleled precision, resolution, and speed. Access a comprehensive range of industrial-grade printing materials. There’s a printer for every application.

Not forgetting the Markforged Metal X, the ultimate metal 3D printer. This Markforged 3D printer utilises a process called Metal FFF to print parts in powdered metal surrounded by a plastic support. The parts are then sintered in a furnace externally to become solid. This enables you to manufacture metal parts with geometries and details that would be impossible with subtractive manufacturing processes. The Markforged Metal X is the most intuitive, simple to use metal 3D printer available today.

The Markforged 3D printers are industry-leading and are capable of printing strong prototypes and end use parts, with good quality finish. Markforged is dedicated to providing industrial-grade reliability and consistency, their adaptable additive manufacturing platform seamlessly integrates into any workflow. Additive-X is proud to be a long-term collaborator of Markforged, a company known for redefining manufacturing through innovative additive technology. The Markforged mission is to bring industrial production to the point of need. Markforged as well as Additive-X want customers to quickly solve manufacturing problems, with additive manufacturing. At the Additive-X HQ warehouse we have lots of Markforged stock available for you to order from the Markforged accessories to consumables. Please note if you are ordering a Markforged 3D printer this will be on a lead time.This is a brand you can rely on to deliver consistency every time. Markforged offers a simple, smart, scalable additive manufacturing platform designed to seamlessly fit into your operation. Eiger software was built for scale delivering a single user-experience, digital part repository and fleet management across the entire Markforged portfolio.